Fuel delivery is the lifeblood of any automotive engine. A smooth, consistent flow of fuel ensures optimal engine performance, efficiency, and reliability.

As vehicles become increasingly high-performance and emissions regulations tighten, upgrading fuel delivery components is no longer optional—it’s essential.

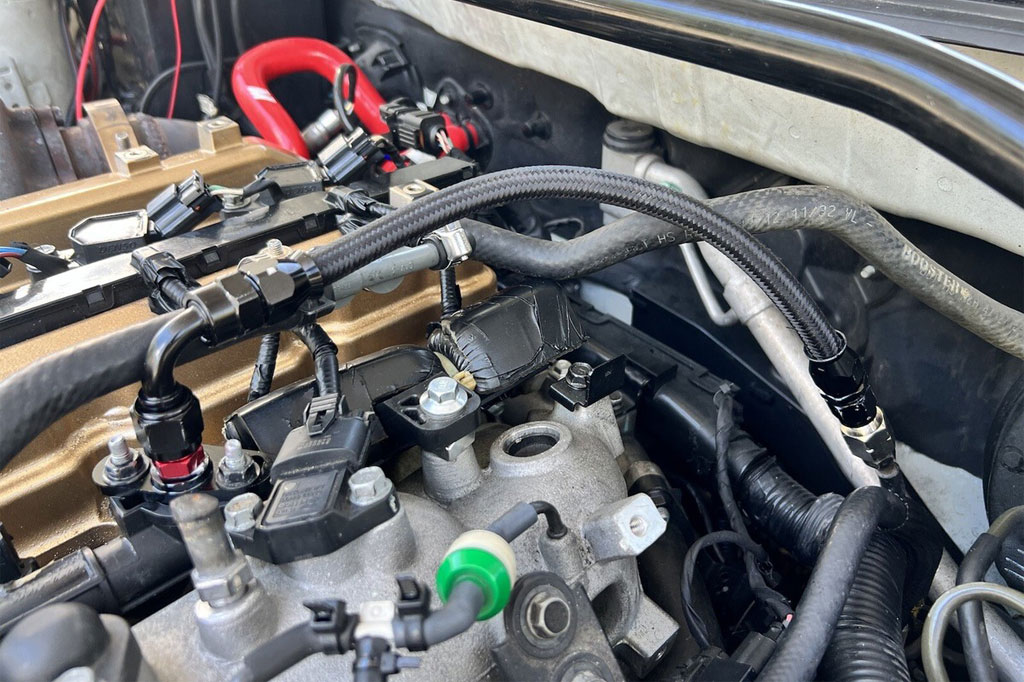

One of the most effective ways to enhance fuel delivery is through PTFE hose upgrades.

What Are PTFE Fuel Hoses?

PTFE is a synthetic fluoropolymer renowned for its chemical resistance, high-temperature tolerance, and low friction surface. PTFE fuel hoses consist of an inner PTFE liner, often wrapped in stainless steel braid for reinforcement, and protected by an outer layer designed for abrasion resistance.

These hoses are commonly used in performance, racing, and high-demand automotive applications.

Why PTFE Hoses Improve Fuel Delivery?

1. Reduced Friction for Smoother Flow

PTFE’s ultra-low friction surface minimizes resistance inside the hose, allowing fuel to flow more freely compared to traditional rubber hoses. This ensures the fuel pump operates efficiently and maintains consistent pressure, especially in high-demand scenarios.

2. Enhanced Chemical Resistance

Modern fuels often contain ethanol, additives, or biofuels that can degrade standard rubber hoses over time. PTFE hoses are highly resistant to these chemicals, reducing the risk of leaks, blockages, or hose degradation that can compromise fuel delivery.

3. Higher Pressure and Temperature Tolerance

Performance engines, turbocharged vehicles, and racing applications expose hoses to higher pressures and temperatures. PTFE hoses can handle pressures up to 330 kg/cm² (≈4700 psi) and temperatures ranging from -70°C to 260°C, ensuring consistent fuel delivery under extreme conditions.

4. Longer Lifespan

PTFE hoses resist hardening, cracking, and collapsing over time, which extends the lifespan of fuel lines and reduces maintenance frequency. Their durability makes them a cost-effective upgrade in the long term.

5. Leak Prevention

The combination of PTFE liner and braided reinforcement provides superior structural integrity. This minimizes expansion and deformation under high pressure, reducing the chances of leaks that can cause performance loss or safety hazards.

Key Considerations for PTFE Hose Upgrades

Hose Diameter and Length

Selecting the correct diameter and length ensures optimal fuel flow without unnecessary restrictions or pressure drops. A slightly larger diameter can increase flow rates, but careful calculation is needed to maintain proper pressure.

Braiding and Reinforcement

Stainless steel or Kevlar braiding enhances strength, resists kinking, and protects the hose from abrasion. The right braiding layer depends on the engine’s pressure requirements and the vehicle’s operating environment.

Fittings and Connections

PTFE hoses are compatible with AN, JIC, or OEM-style fittings. Proper fitting selection and installation are critical to maintain a leak-free system and ensure optimal fuel delivery.

Maintenance and Inspection

Even with PTFE hoses, regular inspections are necessary. Look for wear on the outer braid, loose fittings, or signs of heat damage. Routine maintenance ensures that the fuel delivery system continues to perform at its best.

Applications in Modern Vehicles

PTFE hoses are widely used in performance vehicles, racing cars, classic car restorations, and even turbocharged engines. They are particularly beneficial in systems where precision fuel delivery is critical, such as:

- Direct injection engines

- High-output turbocharged setups

- Ethanol or biofuel-compatible vehicles

- Classic cars upgraded with modern fuel systems